Advanced Engineering

-

16%

Lower operating temperatures

With our transformer and line-reactor combo

-

Up to 40%

More horsepower

In the same motor frame

-

30%

Production increase

Proven, with our mining drill automation system

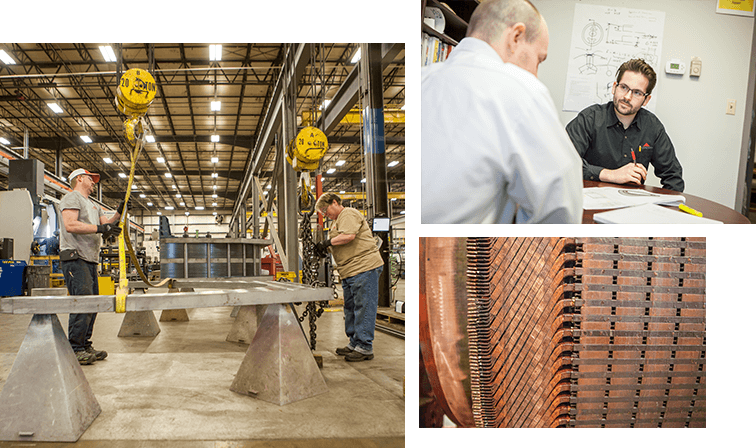

We can manufacture anything we engineer

With our in-house custom manufacturing capabilities, we have end-to-end process control to ensure you get a product of exceptional quality that meets or exceeds your specifications.

- Custom DC and AC drives and motors

- Horsepower upgrades and DC drive retrofits

- Generators and alternators

- Transformers

- Industrial and portable switchgear

- And any other component of electric rotating equipment or control systems

-

Power system engineering—and reengineering

Developing the first DC to AC dragline retrofit in North America

-

Purpose-engineered FLANDERS AC drives and motors were the foundation of the DC to AC conversion we did on a 50-year-old Bucyrus Erie 770 dragline for a Kentucky coal company. The high-efficiency drop-in motors and drives that we used required no structural modifications, eliminated noisy DC generators, and delivered more power.

Less than a year after commissioning, the dragline was two months ahead of dig schedule, consistently outperforming newer machines.

-

-

Drive system upgrades for coordinated systems

Replacing 110 drives for a total hot mill automation upgrade

-

A large international mill builder and automation provider enlisted FLANDERS to supply 110 DC drives and all related engineering, design, installation, and commissioning for a complete aluminum hot mill automation upgrade in Texarkana, Texas.

FLANDERS first performed a detailed engineering study to understand the mill’s performance requirements in depth, and determine the most cost-effective way to update the drive systems. Based on the study findings, our engineering team defined the optimal solution as

- New Siemens 6RA70 DC drives, configured to communicate with the mill control system by way of PROFIBUS DP

- Re-using the original ASEA DC drive power components for the main stand, unwind, and rewind applications, and using new 6RA70 control modules to control the power sections.

- Completely replacing the enclosures and power components for all other drives with FLANDERS hardware and technology

FLANDERS also provided an installation package that included around-the-clock installation supervision and assistance to ensure timely, successful completion of the project.

Highly satisfied with our comprehensive drive system solution for their hot mill, the client has since contracted with FLANDERS for several additional projects.

-

FLANDERS upgrades can take a machine’s production and lifespan from good to great. We work with your maintenance and production schedules to minimize interruptions and make sure the work is performed at the optimal time for your team.