Oil & Gas

Our hands-on experts in electric rotating equipment are ready to serve: upstream, midstream, and downstream.

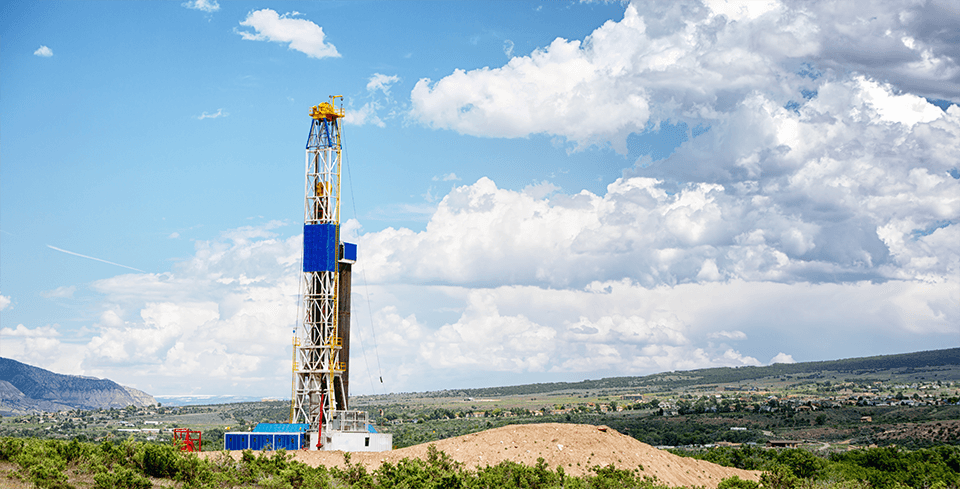

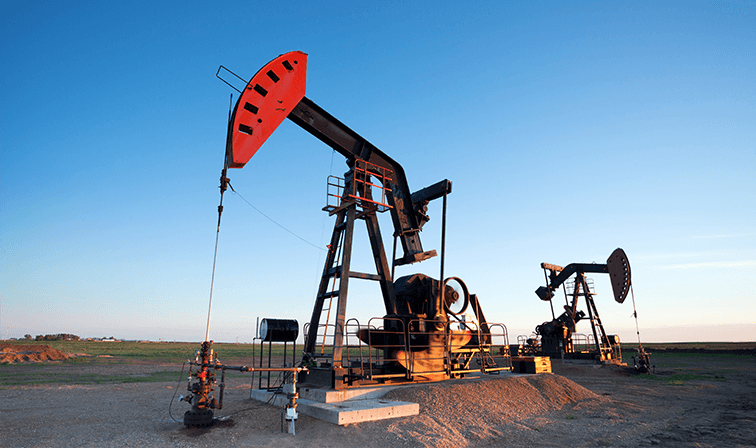

Upstream

Onshore and offshore

The FLANDERS field service team has full electromechanical repair capabilities that include onsite and onboard cryogenic cleaning, commutator turning and undercutting, and rewinding for large electric motors.

We also service, rebuild, and upgrade submersible pumps, generators, cranes, and electric propulsion motors. There is no field service need too small or too large for FLANDERS.

Time is of the essence in the fast-paced environment of drilling and producing oil and gas, and our rapid-response team will keep your wellhead moving.

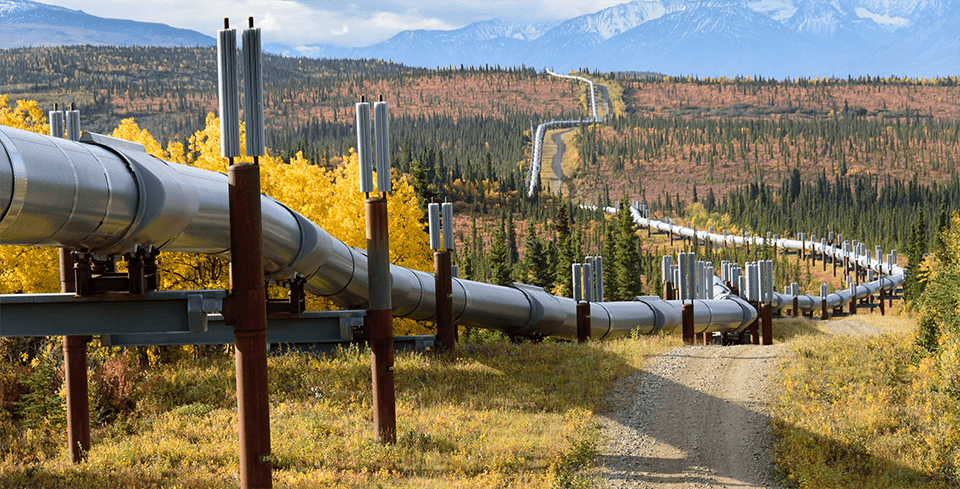

Midstream

Purpose-built FLANDERS motors for pipeline pumps last longer and require less maintenance than conventional motors, so they’re a great fit for remote installations. We’ve been installing, repairing, and replacing oil pipeline pump and compressor motors for decades. We frequently do switchgear retrofits for midstream pipelines as well.

Downstream

FLANDERS supports oil refineries with electric motor upgrades, power system maintenance, 24/7 emergency troubleshooting, and extensive testing abilities.

Our power systems experts also modernize substations to increase the transmission capacity, stability, and quality of your power supply with improved technologies.

Across North America—and worldwide—we have a lot of aging, inefficient Oil & Gas infrastructure. That’s a recipe for high energy costs and unplanned downtime. The FLANDERS team does a lot of pipeline upgrades with variable frequency drives and our own high-efficiency medium-voltage motors.

When you need electric motor service 100 miles from nowhere, our expert oil and gas field techs are ready to deploy on a moment’s notice.

Services for oil & gas

Experts in controls and electric rotating equipment

Field services

Our Oil & Gas field services team offers onsite machine audits, predictive maintenance (PdM), 24/7 troubleshooting and repairs, and field installation of drives, pump motors, generators, alternators, transformers, switchgear, PLCs, and instrumentation.

Learn MoreRepair, rebuilds, upgrades

If it’s an electronic system or an electric rotating machine, we can fix it, rebuild it, upgrade it in our UL-certified shops. Our Motor Exchange Program keeps downtime for change-outs to an absolute minimum, so your extraction and delivery stays on schedule.

Learn MoreSystems integration

The FLANDERS systems integration team develops and optimizes solutions on all major industrial controls and automation platforms—ABB, Siemens, Toshiba, and Rockwell Automation. We also develop and integrate custom PLCs.

Learn MoreAdvanced engineering

As a design/build R&D house specialized in electric power systems, controls, and automation for hazardous or severe-duty applications in heavy industry, we’d love to partner with you to develop new and better technologies for your Oil & Gas operation.

Learn MoreCustom manufacturing

Our master craftsmen can remanufacture obsolete parts, custom manufacture better motors, or even do short-run manufacturing of parts and assemblies to your specifications.

Learn MoreTesting & diagnostics

We have state-of-the-art test facilities for the largest motors used in heavy industry, and we pre-tune every motor that leaves our shop—whether new or repaired—for faster commissioning in the field.

Learn More