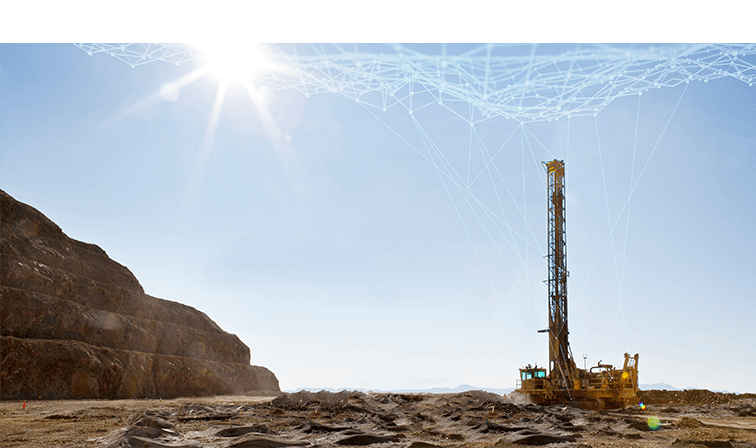

FREEDOM for Drills

-

Gains

In Productivity

Improve productivity in the toughest conditions with ARDVARC Intelligent Drilling - Collaring

-

Efficiency

In Operation

One operator can run multiple drills remotely from a central location away from the pit. Reducing costs with additional productivity.

-

Control

Risks

Control risks by allowing drills to be operated from a distance.

Blasthole drills run by our automation system have drilled millions of holes. In addition to increasing hole-to-hole drilling speed and precision, our automation system eliminates operator errors that could otherwise take a drill out of production for an extended period of time.

Agnostic Drill Automation Offerings

FLANDERS technology is agnostic to any drill rig on the market (diesel or electric), and its open-architecture control system will enable mine sites to modernize mining drills with industry-leading automation and machine health monitoring capabilities.

ARDVARC Features

Services for drills

Having developed the world’s first automated blasthole drill, you can be certain we know everything there is to know about drill controls and electronics; we’re the hard-working, hands-on experts you want on the job.

- Field services

-

From troubleshooting drill hydraulics to preventative maintenance to total control system replacements, our drill experts are ready to help with anything you need in the field.

-

- Advanced engineering

-

Our engineering team specializes in developing new and improved technologies for severe-duty machines with electric rotating systems, including drills, shovels, draglines, and haul trucks.

-

- Custom manufacturing

-

If we can engineer it, we can build it. We’re even a motor and drive manufacturer for a number of OEMs in mining and other industries.

-

-

From troubleshooting drill hydraulics to preventative maintenance to total control system replacements, our drill experts are ready to help with anything you need in the field.

-

Our engineering team specializes in developing new and improved technologies for severe-duty machines with electric rotating systems, including drills, shovels, draglines, and haul trucks.

-

If we can engineer it, we can build it. We’re even a motor and drive manufacturer for a number of OEMs in mining and other industries.