Mills

We’re standing by to make your mill smarter, faster, safer, stronger.

Metal mills

FLANDERS works with steel and aluminum mills across North America and around the world.

We’ve developed custom mill motors and drives specifically for the harshest mill environments. Our solutions withstand the high temperatures, high humidity, scale dust, heavy loads, and continuous operation that define severe-duty requirements in metal mills.

Paper mills

The many machines involved in paper mills offer many opportunities to improve both stand-alone and coordinated systems for higher efficiency and production.

We collaborate with paper mill operations teams to upgrade their machine power systems, modernize their control systems, and develop custom motors, drives, PLCs, and automation systems for these specific purposes.

Motors and drives for auxiliary equipment

We carry—and repair—a full range of smaller motors, including low horsepower NEMA-frame motors, for auxiliary mill machines. Plus, we’re a distributor for many leading brands, including ABB: Baldor/Reliance, GE, Lesson, Lincoln, Marathon, Toshiba,

US Electric: Nidec, and WEG.

Motor Exchange Program

Our Motor Exchange Program is especially popular with milling operations because it reduces overhead costs for keeping critical spares on hand. When your mill motor needs in-shop repairs, we’ll quickly deliver and install the spare we keep for you in our inventory. That way you’re up and running while we fully recondition the original motor, which then becomes your new spare.

Our power system design/build capabilities give our systems engineers a lot of flexibility in developing site-specific solutions to increase mill productivity and reduce energy consumption.

Services for mills

Seasoned experts in electric systems of all kinds

Field services

Our specialized mills field services team is available 24/7 to keep your mill operation up and running smoothly, with everything from emergency troubleshooting to onsite motor rewinding to rapid motor exchanges.

Learn MoreRepair, rebuilds, upgrades

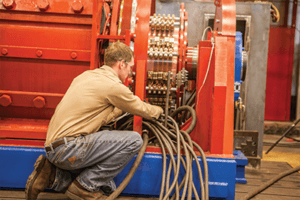

We can refurbish or upgrade any large electric rotating apparatus in your mill: main-stand critical spares, hoist motors, roll table motors, submersible pumps, MG sets, and more.

Learn MoreSystems integration

From new safety-system PLC development to complete automation system modernizations, our experienced systems integrators can convert outdated control systems to state-of-the-art.

DC to AC upgrades

For the right mill application, an upgrade to AC drives and motors can transform machine performance with greater horsepower, peak power, torque, speed, control, and efficiency. FLANDERS can retrofit any DC machine in your operation for AC.

Learn MoreAdvanced engineering

We partner with mill operations to develop improved motors, drives, control systems, and even completely novel mechatronic technologies. We can also reverse engineer—and manufacture— replacement parts for obsolete systems.

Learn MoreCustom manufacturing

For mill operations, we manufacture DC and AC motors up to 110 tons for critical spares, drop-in replacements, and upgrades. This includes new and custom motors, MG sets, transformers, and replacement parts.

Learn MoreTooling & die-cutting

If you need custom process tools, FLANDERS has an in-house team with cutting-edge capabilities in tooling and die-making.

We also develop new automated machines for manufacturing processes.

Learn MoreTesting & diagnostics

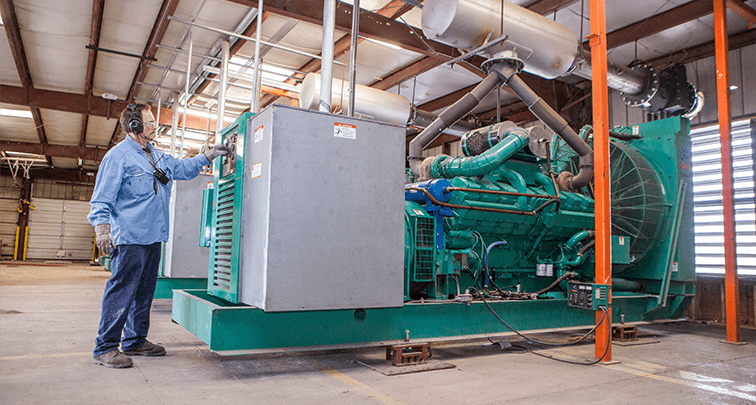

Whether we’re megger testing motors in the field, load testing a newly manufactured 10,000+ HP motor, or running diagnostics on a critical spare that we have in the shop for repairs, FLANDERS has full in-house capabilities for testing electric rotating equipment.

Learn More